Portable and Fixed Systems to monitor all parameters of biogas composition and on different biogas sites.

Complete solutions to meet any project design, ATEX certified gas monitoring equipment and ISO accredited.

Continued after sales support and maintenance options are available to ensure the longevity of your instruments.

1. Handheld Gas Analysis Instruments

Lightweight, hand-held instruments for site investigation, landfill and compliance Gas Analyser that has been designed and manufactured for use in the most challenging field conditions.

Portable units available with either Multifaction capabilities OR with a Standard 4 Gas measurements.

Both offered with a large battery life allows detailed gas analysis to take place for extended periods of time.

The instrument allows the measurement of the gases in landfill management and is designed to help landfill engineers minimise down time and maximise efficiency.

Optional temperature sensor can be plugged in for gas temperature measurements or, alternatively, a vane anemometer can be attached to measure the velocity in a gas extraction system pipeline.

![]() Multifactional Portable Analyzer

Multifactional Portable Analyzer

2. Fixed Gas Systems

Configured specifically for biogas sites.

Designed for easy self-maintenance and expansion, Fixed systems give users greater flexibility over traditional on-line gas monitoring systems.

A typical system installation contains all the necessary component parts such as gas analyzers, pumps, filters and switching valves that have a working or calibration life,

and would possibly need to be changed during traditional service visits.

Designed for reliability and long service life downtime and minimized service visits.

Basic operational maintenance can be conveniently carried out by a qualified electrician.

Data logging options available.

All data can be downloaded either to a SD card or remotely using GSM/GPRS, MODBUS, PROFIBUS allowing customers to generate reports and view all data online.

This remote communication also allows users to enter gas alarm trigger levels and generate email and text alerts.

The facilities also allow access advanced diagnostic tools and carry out software updates as required.

3. Gas Detection Safety Systems

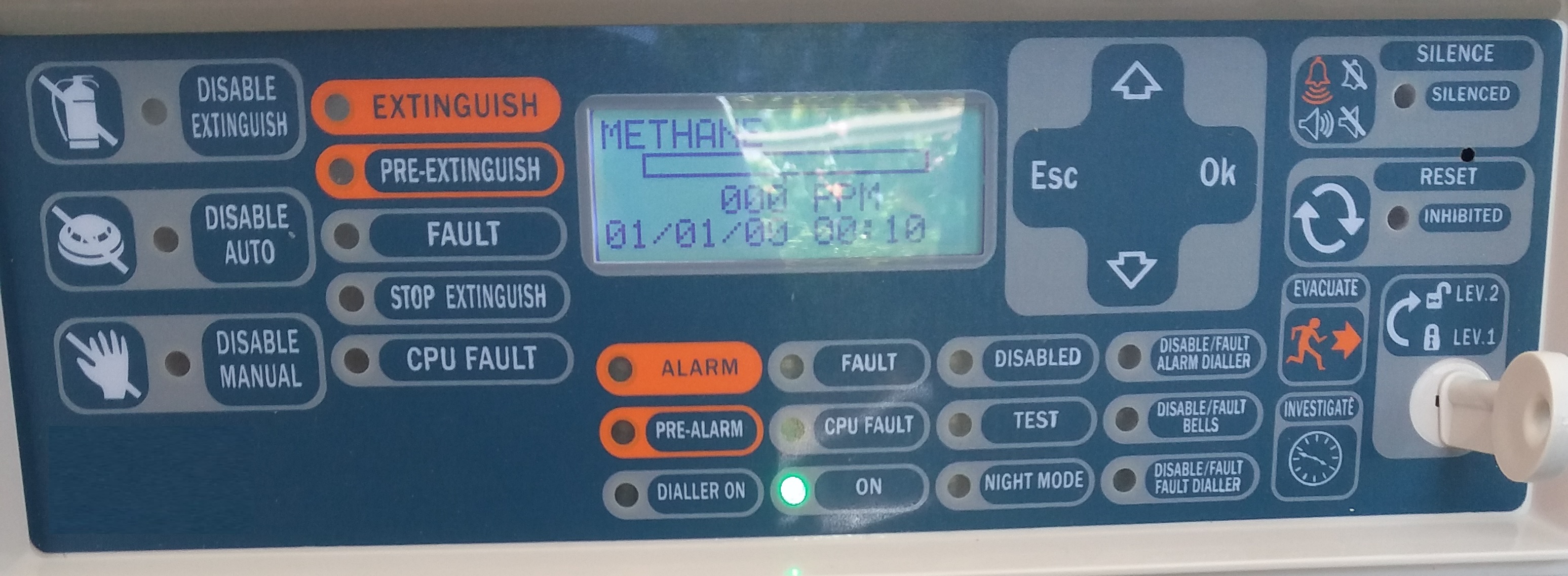

Gas Detection Control Panel

The Gas Detection control panel manages up to 20 conventional detector lines (zones) for SL-020 models or up to 36 lines for SL-036 model.

Each line (zone) accepts up to 30 devices and is provided with an additional I/O line that can be configured as an open-collector output (the activation principles can be defined during the configuration phase) or as an independent input line (separate from the zone) for fire detection, gas detection line, etc.

The available control panel models are:

• SL020-2 - with 2 zones non expandable

• SL020-4 - with 4 zones expandable to 20

• SL036-4 - with 4 zones expandable to 36

MAIN FEATURES

SL020 / SL030

|

AC POWER |

230VAC +/- 10% |

|

Frequency |

50Hz |

|

Nominal output voltage |

27,6V |

|

Maximum output current |

2.1A / 5.2A |

|

Imax. a |

1,5A / 4A |

|

Maximum battery current emission during primary power failure |

1,5A / 4A |

|

Maximum current for external loads and accessory devices |

1,41A / 3.91A |

|

Maximum current draw on terminal + AUX |

0.8A |

|

Maximum current draw on terminal + AUX-R |

0.8A |

|

Maximum battery-charge current |

0.6A / 1.2A |

|

Battery specifications |

2 x 12 V, 7 Ah / 2 x 12 V, 17 Ah |

|

Maximum internal resistance of the batteries (Ri max) |

2.7 Ohm / 1 Ohm |

|

Output voltage |

2.7 Ohm / 1 Ohm |

|

Battery shutdown tension |

2.7 Ohm / 1 Ohm |

|

Internal fuse of switching power supply module |

T 3.15A 250V |

|

Maximum output current ripple |

1% |

|

Operating temperature |

from -5°C to 40°C |

|

Isolation class |

I |

|

Enclosure protection class (EN 60529) |

IP30 |

|

Dimensions |

325 x 325 x 80 mm / 497 x 380 x 87 mm |

|

Weight |

325 x 325 x 80 mm / 497 x 380 x 87 mm |

All control panels from the SL series are EN54-2, EN54-4 and EN12094-1 compliant.

|

|

Photos might change without prior notice.

METHANE DETECTOR

The 295 series is a three-wire 4÷20mA transmitter able to detect combustible gases by employing a catalytic sensor calibrated up to 20% LEL to different gases and find their best application in centralized alarm systems.

The instruments is flameproof certified and comprise of an enclosure in which the electronic circuit and the terminals are mounted and a downward facing cylindrical sensor housing with inside a replaceable “Cartridge Sensor”.

The instrument has a 4χ20mA linear output (S) with 20%LIE (Lower Explosive Limit) F.S. of detected gas.

The Printed Circuit Board, F1 and F2 key using for Test and Calibration routine, protected by a code, and 3 LED shows the working conditions:

Red LED "ALARM": 20% LEL alarm indication.

Green LED "ON": normal working condition.

Yellow LED "FAULT": the sensor should be faulty, disconnected, out of scale or expired.

293 Methane CH4 is calibrated to detect Methane, a gas lighter than air. Its density as to air is 0.55 andits LEL (Lower Explosive Limit) is 4.4%volume.

INSTALLATION

it should be fixed at 20-30 cm from the ceiling (the Methane gas is lighter than air).

Average life: The sensitive element used in this detector has an excellent stability in time. In fresh air and in normal working condition the sensor's life is about 5 years from the date of installation. After this period the yellow LED “FAULT” flashes every 4 seconds, is necessary replacing the “Cartridge Sensor”.

Note: the detector is not able to detect gas leaks occurring outside the room where it is installed, neither inside walls or under the floor.

II 2G Ex d IIC T6 Gb

Certificate number: CESI 03 ATEX 323 X

Photos might change without prior notice.

4. Gas Sampling Kit

Landfill Gas Sampling Kit is used for the detection and quantification of many of the gas components found on and near contaminated land and landfill sites.

Serious site investigations should also require periodic verification of on site readings together with quantitative analysis of minor gas components and investigation of the origin of some of the bulk gasses, most commonly methane. This analysis is laboratory based and involves a variety of techniques from Gas Chromatography to Mass Spectrometry.

Gas Sampling Equipment is generally accepted as the most reliable and cost effective method of taking a gas sample for laboratory analysis.

This is due to the ease with which a sample can be taken at the site and the convenience of transporting it to the laboratory for analysis.

A sampling kit weighing only 5 kg and requiring no electrical supply is widely used for most applications.

The compressed sample can be introduced from the cylinder into the analyser via a dosing valve or septum allowing a comprehensive analysis to be carried out from a single sample.

The cylinders used are extremely durable and are available in aluminium alloy and stainless steel.

At the recommended pressure of 14 Bar the most popular 55ml cylinder will contain nearly 0.75l of sample gas at atmospheric pressure.

Gas Sampling Kit contains:

- one Gas Sampling Pump

- six 55ml Stainless Steel Sample Cylinders

- Filling Indicator

- Purging Attachment

- Connecting Tube

- Spare Valves with Insertion Tool

All items in the Kit are available separately