ENCLOSED FLARE UNITS

The GF10 range fully comply with the latest and stringent emission standards within EU, including TA Luft and UK’s Environment Agency whilst minimize energy requirement. A PLC continues monitor the optimum combustion temperature automatically regulating forced air draught in the fuel/air mixture in the combustion chamber. Cyclonic burner provides residence time >0.3 sec. This results combustion temperatures between >1.000°C up to 1.200 °C thus results to low emissions. The GF10 range comes in various flow rates starting from as low as 50 m3hr1 through up to 6000 m3hr1.

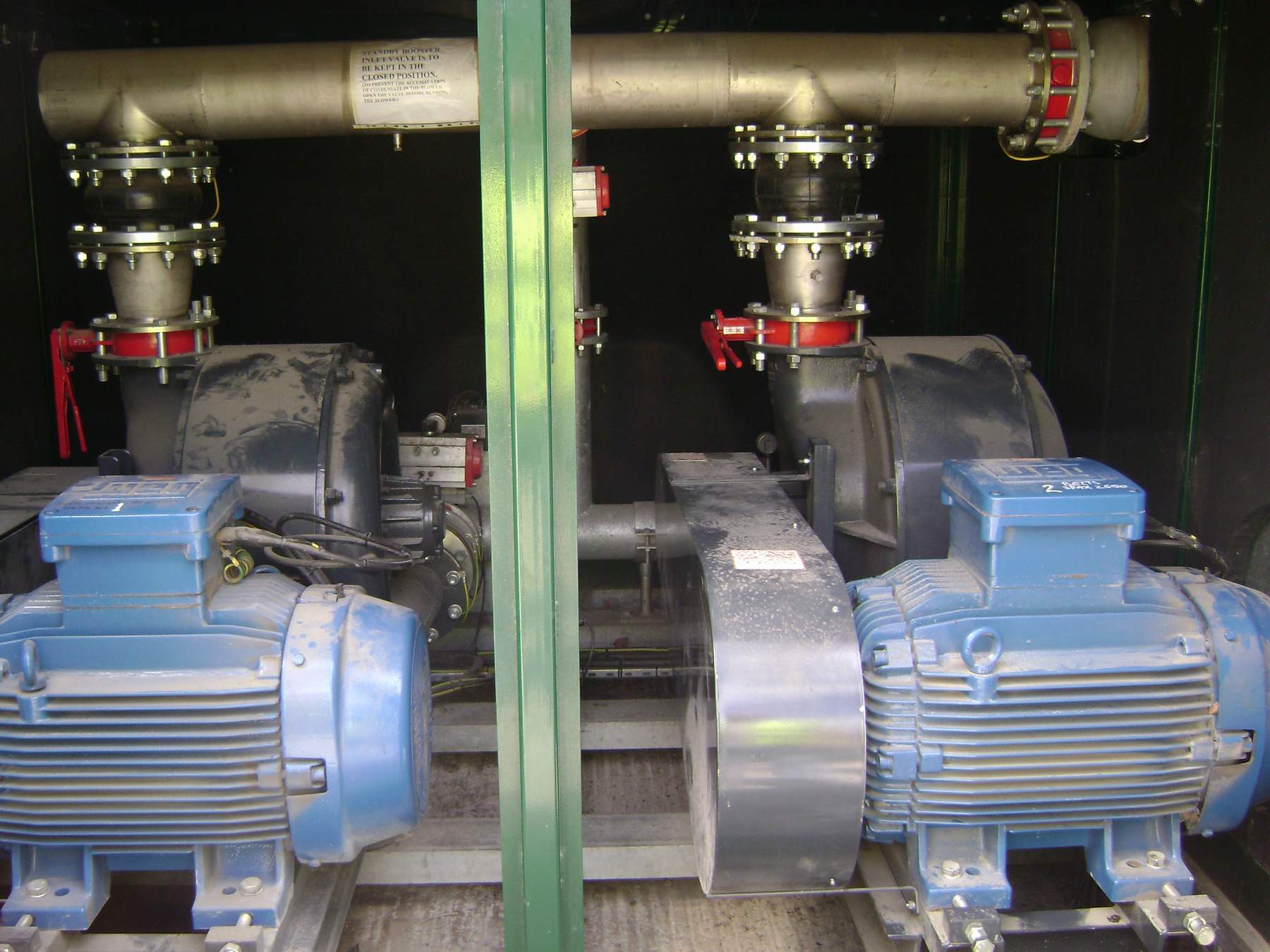

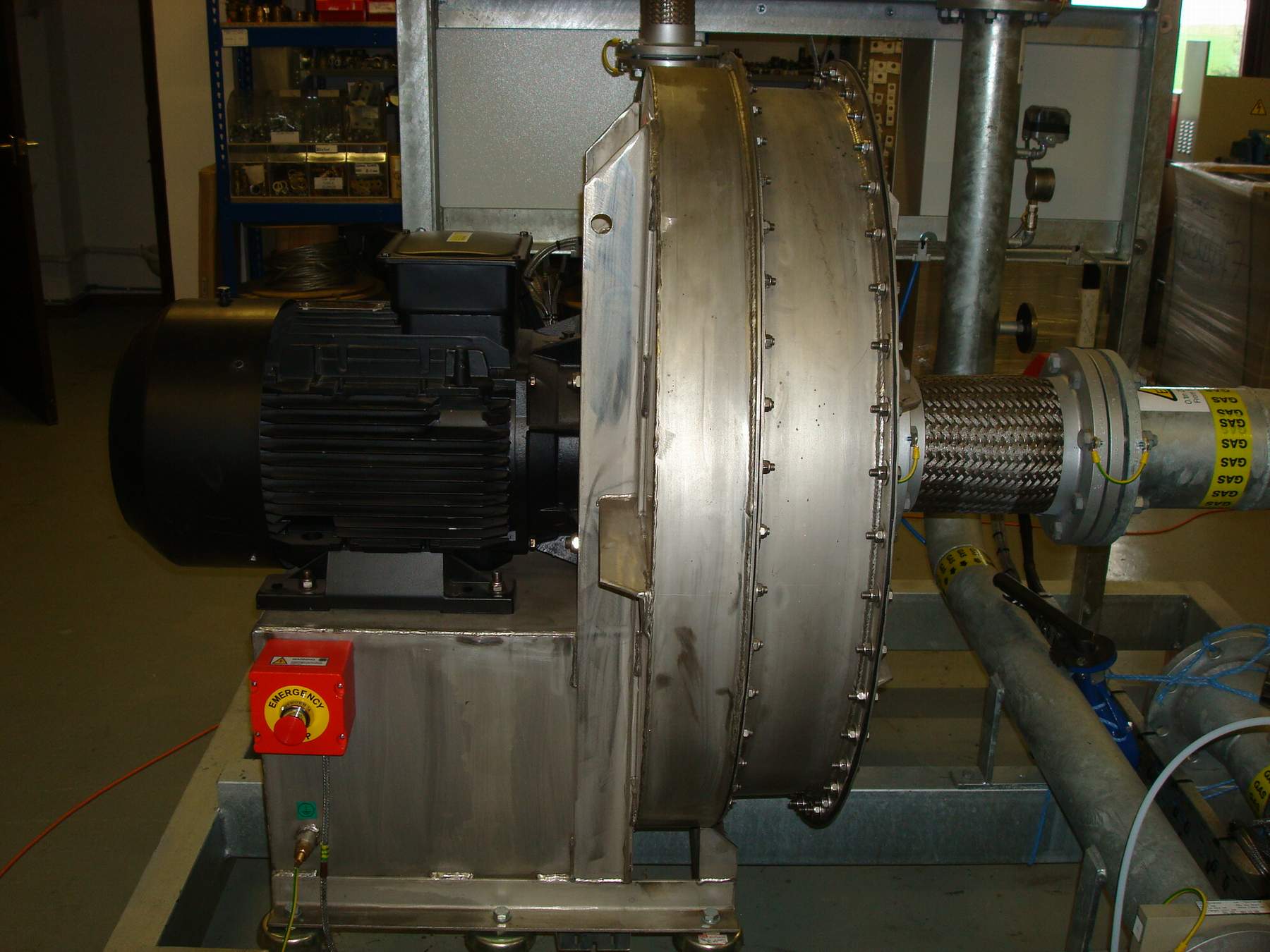

Also the GF10 range may in different configurations be used as part of a Utilization project, Containerized, Single orTwin stage blowers, Duty-Standy or Duty-Duty.

Downstream of the booster:

-Inlet flange with manual lever operation isolation valve

-Vacuum pressure & temp gauge

-Gas sample port, , flow indicator manometer or digital read-out.

-Galvanized Condensate knockout pot

-Polypropylene demister element,

-Pressure gauges across the demister

-High condensate level switch

-HDPE condensate drain lance and liquid seal vessel

Gas Booster:

-Centrifugal blower, in mild or stainless steel, ATEX compliant,

-Direct drive, Star-Delta starting.

-“Motor trip” automatic cut out function onto the control panel.

Upstream of the booster:

-Fan outlet pipe c/w vacuum pressure & temp gauge

-Gas sample port, Anemometer inlet

-Manual lever operation burner control valve

-Pneumatic operated safety shut-off valve

-Deflagration ATEX flame arrester

-Provided with pressure gauges and temperature sensor

-Pilot burner gas train

Flare Stack:

-High temperature stainless steel burner

-Galvanized steel combustion chamber

-125mm thick 1265°c 128kg m-3 ceramic fibre insulation

-Spark ignition into pilot burner

-Flame monitoring (°C PID adjust & display), UV sensor,

-Modulating damper, electrically actuated

-Automatic temp controlling thermocouple

Options:

-Multiple inlet manifold, Stainless steel Pipe work,

-Stainless steel Condensate knockout pot,

-Stainless steel demister element,

-Pumped drainage system, Τrace heating and insulation,

-Orifice plate flow meter,Thermal mass flow meter,Twin stage blower, Acoustic enclosure,Digital transmitter display on control panel,Low pressure switch, Gas analyser inlet,

-Gas fan inlet ATEX flame arrester, Belt drive,Inlet gas analysis system,Pressure digital transmitter in mbar on control panel,Data logging & Telemetry

-Other options available to suit customer requirement Electric operated safety shut-off valve

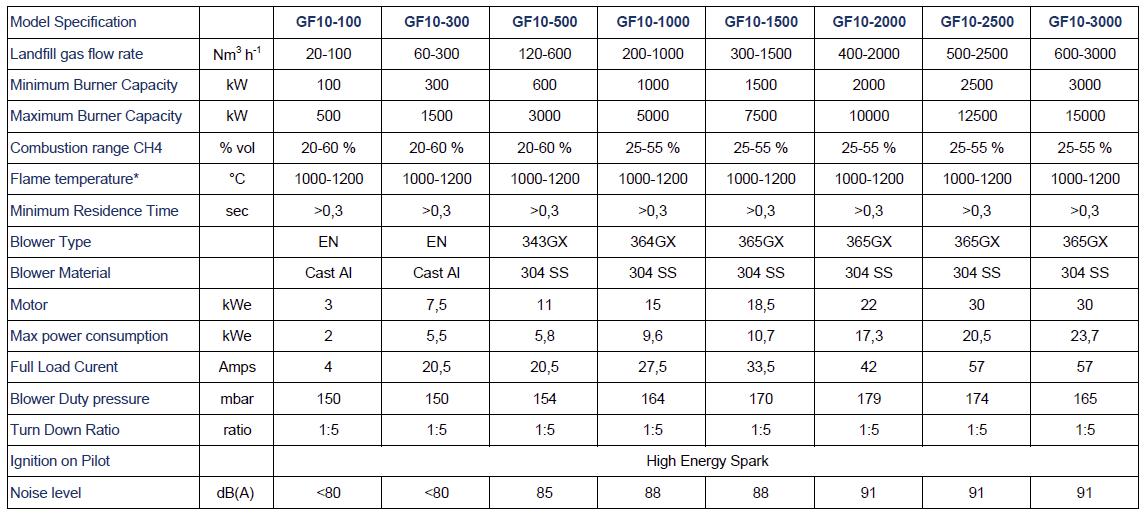

General Specifications:

__________Direct - drive twin stage blower_________________Belt drive Duty - Standby blowers_________