HDPE is the industry’s recognised material for use within landfill for gas and leachate extraction.

The stress and strain imposed on vertical HDPE pipes in landfills is immense due to the large amount of settlement which occurs within the waste itself.

Vertical pipes are subject to the resultant of axial and radial stresses, but the axial stress is much higher and by far the most damaging.

The damage occurs because the axial strain and consequent stress exceeds the buckling strength of the pipe.

The axial stress is caused by ‘skin friction’ between the outside wall of the pipe and the surrounding waste as it settles.

Loads as high as 100Tf are not uncommon.

If axial movement can be accommodated during settlement then the axial stress is eliminated.

ACCOMODATION OF STRAIN = NO STRESS

To minimise the stress on a vertical shaft in landfill it must meet the following requirements:

- Move axially during settlement

- Act as a column and not as individual sections

- Have minimum lateral deflection at joints

- Able to accommodate settlement over the entire

- length including the bottom section

- Be built up in sections as fill occurs

- Accommodate settlement over 30%

FEATURES

- High ring stiffness HDPE pipe.

- Tested shear ring strength.

- Known shear pin strength.

- High penetration ratio.

- Minimal lateral movement at joint.

- Acts as a single column.

- Bottom section can move.

- Standard 3meter sections.

- Same wall thickness throughout.

- Easy to install.

- Granular fill only needed on base.

- Settlement over 30%.

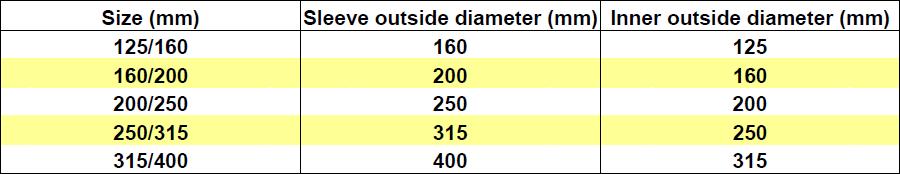

- Diameters from 100 to 1600mm.

- Design calculations provided.