GeoPumps

The efficiency of a landfill gas extraction system is well dependent on how we manage to control leachate and condensate. High levels of leachate seriously affect the ability to extract landfill gas because landfill gas can not be extracted below liquid level and if condensate cannot drain from the collection system leads to hydraulic locks. Landfill gas extraction system efficiency can be improved by the installation of leachate pumping systems.

The GeoPump™ range of pumps is an automatic, inherently safe pneumatically operated pump which can be used for a wide range of applications including landfill sites but also groundwater remediation applications where explosive environments exist.

It can be arranged to fill from either the top or the bottom to suit different

applications.

Features

- Reliability

- Low maintenance

- Low operating costs

- Intrinsically safe

- Completely automatic

- Low air requirement

- Self adjusts to well flow

- Does not need high quality air

- Pumps solids in suspension

- Long lasting

- Simple and easy to use

- Can be placed into ID >45mm wells

PUMPING CAPACITY

As liquid enters the GeoPump™ under gravity and exits under the pressure of compressed air the performance of the GeoPump™ is dependent on several factors which include :

- Depth of liquid above pump inlet (submergence)

- Operating air pressure

- Internal diameter of hoses used

- Total dynamic head

Materials

- Stainless steel

- Polyethylene

- Viton ®

- Fibre reinforced plastic

- Kynar ®

- Teflon ®

how it works....

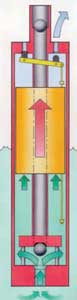

The GeoPump™ is operated by compressed air and features an internal float which automatically controls the pump itself and regulates the liquid level. It may be installed for shallow or deep wells and operates automatic only when is full with liquid to be pumped thus minimising conserving energy.

Fill Cycle

Pump starts to fill

The inlet non-return valve opens, allowing fluid to enter the pump.

As the fluid level in the pump rises, the internal float rises to the top of its stroke.

In this upper position, the float actuates a lever assembly to open the air inlet valve, and compressed air enters the pump chamber.

Note: No air is used during the fill cycle.

Empty Cycle

Pump starts to empty

The air pressure within the pump chamber causes the fluid inlet valve to close.

The fluid is then displaced from the pump chamber up through the discharge pipe.

As the fluid level in the pump is lowered the float actuates the lever to close the air supply and open the air exhaust valve.

A new cycle begins.